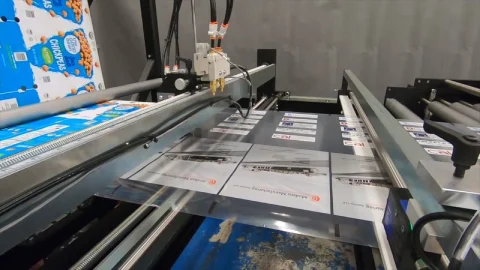

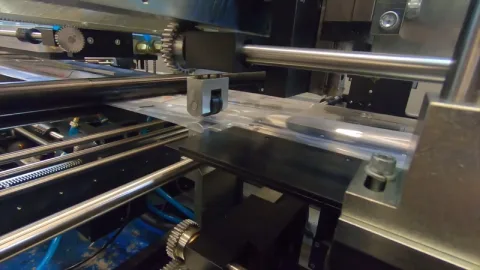

Velocity-610

The Velocity-610 Stand-up pouch making machine is ideal for medium to high volume runs.

Get a quote

Mid to High Volume Runs

The machine is designed with the same set-up features as Modern’s Momentum series but offers a more fully-featured line with higher thru-put speeds. With the shortest change over times in the industry, the Velocity series sets the bar for optimum pouch quality.

Standard Features Included

- Independent servo draw systems

- Servo knife with independent servo sealers/coolers

- Built-in flange zipper system

- Five-zone web-tension control (updated from four-zone)

- Nip-driven unwind system

- Built-in indexing conveyor

- Two independent punch carriages (one with tear notch and one with hanger hole)

- Digital temperature controls

- Heater and thermocouple break alarms

- Eye averaging function (smoothing function)

- Built-in 2nd cut feature

- Additional inline seals and cross seals (enables higher speeds and more pouch configurations)

Pouch Configurations

Three side seal

Header seal

Three side seal with zipper

Stand-up Doyen seal tooling required

Stand-up angle seal

Optional Pouch Configurations

Quad seal

Side gusset

Slider zipper

Corner round

Bottom-load

Velcro zipper

Shaped pouches

Equipment Options

-

Optional Punch Shapes and SizesTear notch, hanger hole, sombrero, corner round, handle hole.

-

Digital Readouts for Carriage PositioningProvides a more precise location positioning with absolute or incremental settings. Inch and metric conversion provided.

-

Closed Loop Chiller SystemFor maintained chilled water supply.

-

Coreless Trim RewinderEasy change spools, traverse wound trim with small foot print.

-

Two Tier Conveyor with Stacking GateAllowing for cleaner stacking and product handling.

-

Vacuum Punch Slug RemovalThis option provides a clean vacuum removal system for punch slugs.

-

Web Tracking GuideGuides film at the front of the machine, allowing better accuracy for punches, web slitting and other pouch features. Eliminates side wander.

-

Auto Stacking and BundlingThis system offers auto stacking and bundling of pouch stacks for high speed operation. Bundled stacks can be set in 20-100 piece counts.

Velocity-610 Specifications

Stand-Up pouch making machine

24 inch (610 mm)

Max lay-flat web width

52 inch (1321 mm)

Max roll diameter

24 inch (610 mm)

Standard core size

3 inch (76 mm)

Min/max gusset size

0.5 inch - 4 inch (1.0 / 8 open) (13 / 102 mm)

Min/max pouch width

3 inch - 12 inch without skip feed (300 inch with skip feed) (51/305 mm)

Max pouch height

24 inch (610 mm)

Mechanical speeds

250 CPM

Electrical requirements

208 / 220 VAC, 125 AMP

Servo actuated machine air requirements

18 CFM @ 90 PSI

Water

12 GPM @ 50-55 °F